The December 2025 advisories published by Siemens and included in the INCIBE-CERT bulletin reveal multiple vulnerabilities in industrial products, control solutions, and critical infrastructure components.

These flaws affect systems used in high-impact sectors: energy, manufacturing, transportation, automation, and essential services.

Among the most relevant points of the notice are:

- Insufficient validation of TLS certificates in IAM and SDK SALT solutions.

- Exposure of sensitive information through vulnerable firmware.

- Risk to the confidentiality, integrity and availability of OT systems.

IT and OT are converging, and these vulnerabilities represent a direct risk to operational processes and, by extension, a potential vector for advanced attacks, including the activation of chains of ransomware attack.

Technical analysis of the vulnerabilities announced by Siemens

Siemens has identified vulnerabilities in multiple components that could allow for interception attacks, data manipulation, and unauthorized access.

Among the most significant are:

- Failures in TLS certificate verification that enable Man-in-the-Middle attacks.

- Exposure of confidential data through poorly secured firmware images.

- Weaknesses in authentication mechanisms and key protection.

These vulnerabilities compromise the security architecture of industrial systems that, in many cases, operate continuously and without room for interruptions.

The threats described are especially critical when the devices are part of the company’s operational perimeter.

A failure in a gateway, PLC, IAM system, or management component can have widespread repercussions across the entire network.

Why these vulnerabilities directly impact industrial safety

The OT ecosystem, by design, prioritizes operational continuity over flexibility. This implies:

- Limited update windows.

- Longer patching cycles than in IT.

- Dependence on legacy components.

- Increasing interconnection between industrial systems and cloud services.

These characteristics turn any vulnerability into a high-severity risk, since an attacker can compromise essential processes or carry out unauthorized actions with physical or economic consequences.

Risk of exploitation: from technical failure to intrusion and extortion

The vulnerabilities described can be used as an entry point for manipulating communications, impersonating systems, stealing sensitive information, or gaining privileged access.

HelpRansomware has observed that current ransomware operations already incorporate OT targets when conditions allow.

In particular:

- A flaw in TLS can allow the interception of credentials.

- An exposed firmware can reveal operational keys or data.

- A vulnerable industrial system can serve as a pivot to IT networks.

In this context, understanding what ransomware is and its evolution towards multiple extortion is fundamental to interpreting the severity of the scenario.

The threats are not limited to encryption. In industrial environments, process manipulation can lead to unplanned shutdowns, equipment damage, or regulatory issues.

Most exposed sectors and actual attack surface

Vulnerabilities particularly affect:

- Energy and utilities

- Advanced manufacturing

- Critical transport and logistics

- Industrial automation and robotics

- Healthcare and laboratories with OT equipment

- Essential service providers

These industries depend on the availability and accuracy of their systems. An intrusion can result in financial losses, operational disruptions, and, in extreme cases, physical risk.

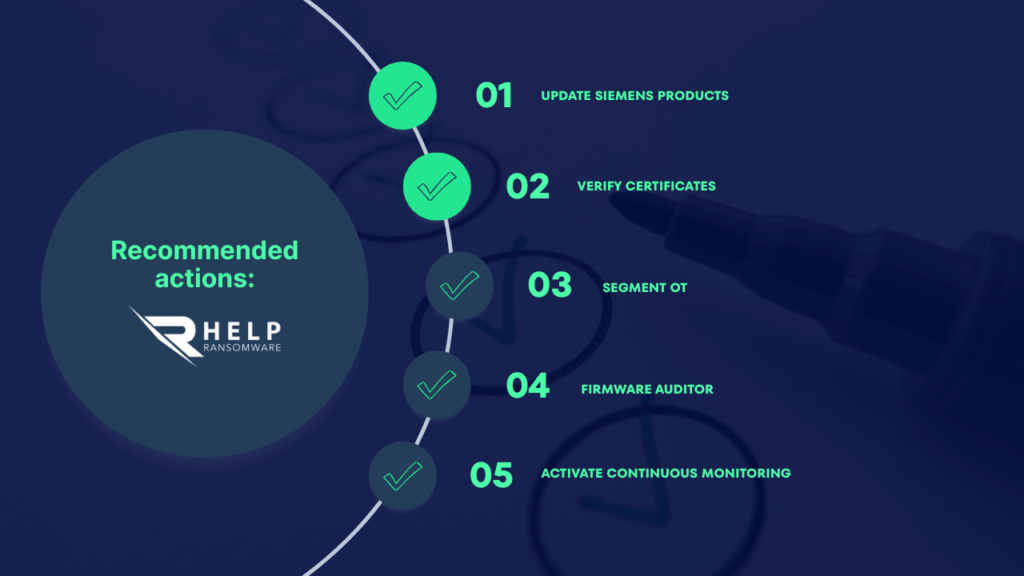

Recommended urgent measures: OT mitigation and resilience

Siemens has published specific updates and recommendations, but OT security requires a broader approach that combines patching, secure architecture, and continuous monitoring.

Recommended actions:

- Apply Siemens updates as soon as they are operational.

- Review TLS certificates, internal keys, and authentication mechanisms.

- Isolate critical OT segments using strict segmentation policies.

- Implement advanced OT traffic monitoring to detect anomalies.

- Perform firmware audits and integrity verification.

- Review external providers, connectors, and dependencies.

In the event of suspicious activity, service degradation, or loss of access, procedures should align with the best practices described for ransomware prevention and, if encryption or locking is present, with What to do if a ransomware attack has encrypted your data.

Proper management of these vulnerabilities requires coordination between IT teams, OT teams, and those responsible for operational continuity.

Conclusion: a new reminder of the fragility of industrial environments

Siemens’ December 2025 warnings demonstrate once again that industrial cybersecurity must be at the heart of business strategy.

High-impact vulnerabilities can become vectors for extortion, espionage, and operational sabotage.

The combination of:

Critical systems, increasing connectivity, lack of regular patches and increasingly targeted attacks form a scenario that requires continuous preparation, vigilance, and a robust response to incidents.

HelpRansomware —an INCIBE-approved company— reminds us that resilience depends not only on technology, but also on processes, culture, and early detection capabilities.